STORMWATER & TRADEWASTE SOLUTIONS

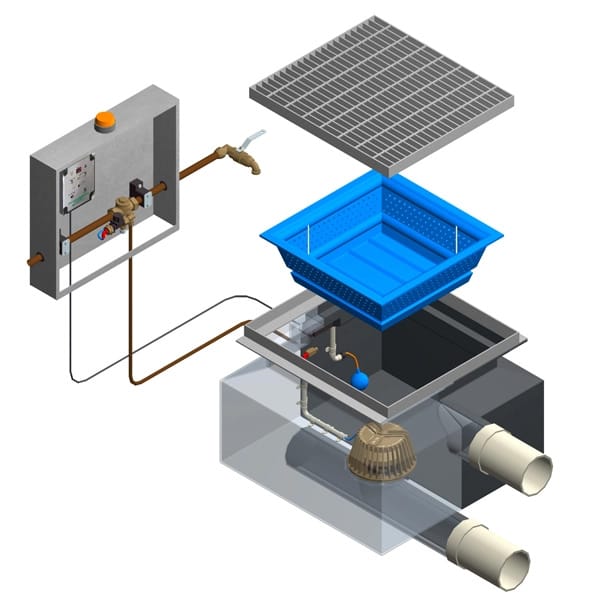

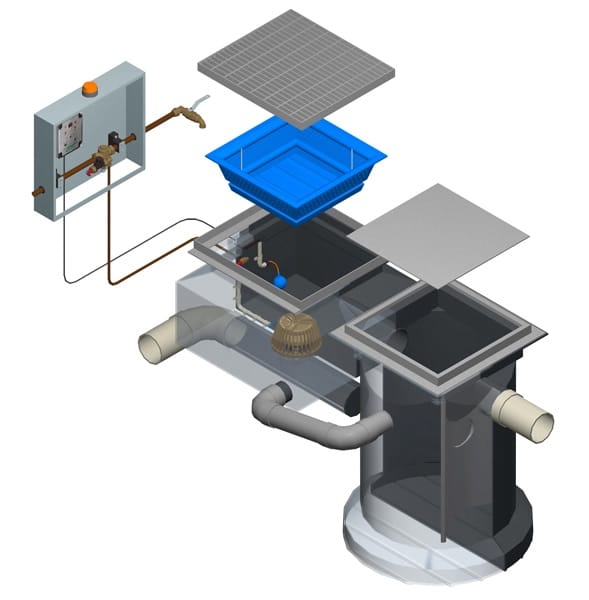

Fox FF600 – First Flush Diversion System for Stormwater and Washdown Bays

The Fox FF600 is an automated first flush diversion system engineered for stormwater runoff control on unroofed wash bays, hardstands, and industrial sites. It captures the initial contaminated flow after washdown and diverts it to trade waste treatment, helping sites meet EPA, council, and AQIS regulations. With its certified design and low-maintenance operation, the FF600 delivers reliable compliance without the need for roofing or power.

Capture Contaminants at the Source – No Roof Required

How do you wash a plane, helicopter, shipping containers, heavy earthmoving equipment or any large mechanical equipment without polluting the stormwater and without installing an expensive roof?

The Fox FF600 First Flush Diversion System provides the answer. It’s designed to automatically divert the first flush of rainfall runoff, the most contaminated portion, to a trade waste treatment system.

Unlike roofed bays or manual diversion setups, the FF600 is:

- Fully automated

- Pre-programmed to activate after washdowns

- Configured to only capture a set volume of runoff, even during intermittent rainfall

This ensures regulatory compliance while minimizing unnecessary treatment and infrastructure costs. It protects local waterways from hydrocarbons, sediments, and other washdown pollutants, without restricting access or adding overhead structures.

Why use a Fox First Flush Diversion System?

- WaterMark Certified – Meets Australian Standards

- IAPMO Certified – Ensures regulatory confidence

- Simple to Design & Specify – Easy for engineers and consultants

- No Above-Ground Obstructions – No pillars, posts, or overhead restrictions

- No Bay Size Limits – Unlike roofing, the FF600 doesn’t constrain layout

- Roof-Free Stormwater Protection – More efficient at keeping rainwater out of sewer lines

- Fully Automated Operation – No manual switching or power required

- Diverts Only the First Flush – Programmed to capture a set volume after washdown

- Low Maintenance – Designed for reliability in demanding environments

- Lower Costs Than Roofing – Significant savings on structure and installation

If hydrocarbon separation is required downstream, a Fox Oil-Water Separator can be installed in conjunction with the FF600.

Compare Models at a Glance

| Model | Best For | Connection Sizes | Access Points | Key Feature | Advantage |

|---|---|---|---|---|---|

| FF600 | Standard trade waste diversion | Inlet/Outlet: DN100 | Control box: 600 x 550 Silt pit: ~775 L | 50L silt basket 1200L/min @ 0.5m head | ✔ Quick install ✔ No power required |

| FF600-BRT | Washdown areas with stormwater bypass return | Inlet: DN100 | Bypass: DN150 | Dual access: Class D grate + bypass | Includes BRT for overflow & debris handling | ✔ Handles stormwater & washdown ✔ Bypass return option |

Related Systems

- Oil-Water Separators – for hydrocarbon capture

- Silt Traps – for sediment control

- Gross Pollutant Traps – for solid waste interception

Protect Stormwater with Certified First Flush Diversion Systems

Fox First Flush Systems automatically capture and divert initial rainfall runoff, protecting your site from contamination while meeting council and EPA compliance standards. Talk to our team to design a solution for your wash bay or hardstand.