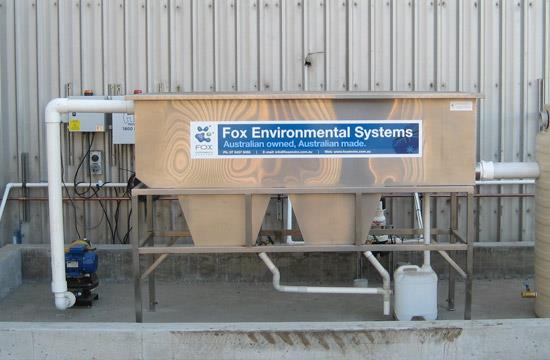

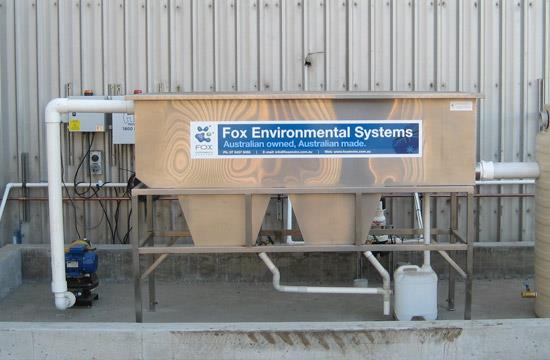

New AQIS Quarantine Plant Wash Bay Installed for Chalmers Transport VIC

Fox Environmental Systems installed a new wash bay for plant and equipment for Chalmers transport company in Yarraville Victoria. Read the case study.

Fox Environmental Systems installed a new wash bay for plant and equipment for Chalmers transport company in Yarraville Victoria. Read the case study.

Fox Environmental Systems installed an approved AQIS wash bay treatment and water diversion system for PIHA, a Perth earth moving business.

Sales & Service Second to None

Are you ready to get started with Fox Environmental Systems? We have a huge range of suppliers across the globe.

Contact us for your local stocklist.

Contact Us Online Call: 07 5437 8455

Quality, Performance, Compliance